|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Scientists |

|

|

|

|

|

|

|

|

|

|

|

About Project

All India Co-ordinate Research Project on Renewable sources of Energy for Agriculture Agro-based Industries Dr. PDKV, Akola Centre Started in 1990 with Thermo chemical conversion technology and Operational Research Project was added during the year 2009.

Infrastructure

All India Co-ordinate Research Project on Renewable Sources of Energy for Agriculture & Agro-based Industries Dr. PDKV, Akola Centre, Department of Unconventional Energy Sources & Elect Engg, is situated at Faculty of Agricultural Engg., Dr. Panjabrao Deshmukh Krishi Vidyapeeth, Akola (M.S). The renewable energy laboratory, improved chulha laboratory, biomass power plant, biogas power plant and other facilities are available with this research project.

Mandate

-

The project is aimed at studying and pilot level field trials on integrated appropriate technology of renewable energy sources viz., solar energy and biomass based gaseous, liquid and solid fuels for their appropriate applications for production agriculture, post-harvest operations, animal raising and rural living, singly or in combination with conventional and other new and renewable energy sources.

-

Operational Research Component of the project aims to demonstrate technical soundness and economic viability of the available renewable energy technologies, in general, and those developed in the project, in particular, for production agriculture, live-stock raising, post-harvest operations, agro industries and rural living in an integrated manner.

Objectives

-

Adaptation / development of solar energy gadgets / technologies for applications in rural domestic & community activities, farming systems and processing & storage of farm produce.

-

Development of technologies & systems for conversion of biomass into solid, liquid and gaseous bio-fuels using biological, thermo-chemical, chemical and mechanical pathways

-

Adaptation of thermal and power systems and gadgets ranging from decentralized power generation units, IC engines and tractors to domestic stoves to work on bio-fuels.

-

Assessment of technical soundness, economic viability and users feedback of new renewable technologies through onsite evaluation.

-

Demonstration of renewable energy technologies successfully integrated into the selected users system and their transfer to industry for commercialization.

Status of Renewable Energy Systems

Among various renewable sources of energy, biomass, which is produced right in the villages, offers ample scope for its efficient use to carry out domestic, production agriculture, livestock raising and agro-processing activities through thermal and bio-conversion routes. During the last about two decades, fairly good number of renewable energy technologies have been developed and commercialized in the region for rural applications.

It has been estimated that about 65-75 % of the total energy consumed in rural sector is for domestic activities such as a cooking and related operations, illumination, water lifting, cleaning, etc. Among domestic activities, cooking consumes around 70-80 % of the total energy consumption. Important sources of energy used for cooking are bio-fuels such as wood and twigs collected from forest, road side plantations, etc, crop residues and cattle dung cakes. Most of the bio-fuels are still burnt in low efficiency Smokey stoves (chulahs).

Research Activities / Achievements/ Recommendations

A. Improved Biomass Cook stoves

Improved biomass cookstoves in a variety of designs, sizes and materials of construction are available to suit requirements of different regions. Important advantages of the improved biomass cookstoves over the traditional chulahas are as follows

- 25-50 % lower wood consumption. This is because of almost double thermal efficiency of the improved stoves as compared to traditional chulahas.

- Very low smoke in the kitchen / house mainly because of provision of a chimney.

- Easier cleaning of cooking pots because of their significantly lower blackening during cooking.

- Lower maintenance of the house because of significantly lower smoke level.

- Better health of people particularly woman and children.

Double pot fixed chulahas designs and single pot portable chulahas designs suiting to cooking requirements of the region is available. Improved mud chulahas involve cost only for asbestos cement (AC) pipe used as chimney.

|

|

|

| Double pot durable stove under regular use in Digras and Manki, Distt: Akola | ||

The salient features of these stoves are as follows

- Option to choose single pot and double pot designs in two different capacities as per requirements

- Thermal efficiency for the single pot design is around 21% & for the double pot around 25%.

- Around 40-50% savings in cooking time and biomass consumption.

- Pollution levels (carbon monoxide, ammonia & methane) reduced by 30-80% compared to traditional stoves.

- Bricks cement, sand and AC pipe are used for construction.

- Cost of the single pot stove is around Rs 200 and that for the double pot stove is around Rs 270.

B. Biogas Plant

Biogas plant is a device in which 1:1 mixture of cattle dung and water is fed and clean burning fuel as a biogas and digested slurry as manure are obtained. All the designs of biogas plants being promoted by MNRE used cattle dung thoroughly mixed with equal quantity of water as feed slurry. The digested slurry discharge from plant is watery and is dried in open pits for a period of 45 days before it becomes suitable for transportation to fields for use as manure. Some of the working plants are rendered unserviceable every year mainly because feeding is suspended due to scarcity of water.

Fixed dome type solid-state biogas plant installed in village

For solving the problem of water scarce regions of the country and of easier management of the digested slurry, the conventional fixed dome type biogas plant designs have been successfully modified under AICRP on RES for digestion of cattle dung in solid state condition i.e. water for mixing with cattle dung before feeding is not required. The main modifications incorporated are as follows:

- The inlet feed chamber of the plant was replaced with commercially available 30 cm internal diameter RCC or rigid PVC pipe.

- The outlet slurry chamber of Janata type plant was enlarged to accommodate total volume of the slurry displaced from the digester. The step type construction of the outlet chamber was changed to an inclined smooth surface for streamlined flow of the digested slurry.

- The outlet channel was widened from 15 cm to 30 cm to facilitate self discharge of the digested slurry on to the ground.

- The interior side of the gas dome was provided with an additional layer of 1:1 cement-sand mortar plaster of about 8 mm thickness to withstand higher gas pressure and to reduce possibility of leakage of the gas.

C. Domestic Solar Dryers

| A high efficiency multi-rack solar dryer developed under AICRP on RES is now commercially available for drying such products at domestic level. The dryer consists of a drying chamber, glazing, drying trays, shading plates, tray support & tray stopper and caster wheels for easy shifting of the dryer. |  |

|

| Portable multi-rack farm solar dryer |

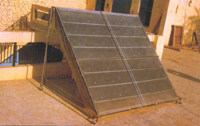

D. Solar Tunnel Dryer

| A number of farm products require drying either before marketing or during primary and secondary processing. Some popular examples are bulk drying of chilies, goose berry fruits and drying of socked paddy grains, chickpea etc. before milling. A walk-in type solar tunnel dryer is now available for bulk drying of farm and agro-industrial products. |  |

|

| Natural convection solar tunnel dryer |

E. Biomass Gasifiers for Thermal Applications and Power Generation

Biomass has traditionally been used for thermal applications in open combustion devices for domestic cooking and agro-processing activities such as jaggery preparation, roasting of grains, etc. Biomass can be converted into producer gas by burning in specially designed devices called gasifiers. The producer gas contains up to 40% of inflammable gases like carbon monoxide, hydrogen and methane.

|

|

|

| Biomass based power generation system (11 kVA) | ||

The producer gas which is very convenient to handle, can be used for various thermal applications such as air heating, baking, roasting, boiling, etc and also as a fuel in IC engines to produce mechanical & electrical power. Biomass gasifiers are now available both for thermal as well as power applications. The gasifier utilizes fuel wood and crop residues as a fuel. The gas produced in the gasifier has high temperature of around 400°C and contains tar and dust particles. For power applications in IC engines, the gas is required to be cooled down and clean of tar and dust particles to a prescribed level to ensure satisfactory operation of the engine.

F. Biogas Plants for Power supply

Cattle rearing and poultry keeping are being practiced on commercial scale in the country. As such large quantities of cattle dung and poultry litter are available from such units. Mature technology is now available for conversion of cattle dung and poultry litter into biogas and manure. Besides thermal applications, the biogas can be combusted in IC engines to produce electricity.

|

|

|

|

Modified Janta Biogas plant (20 m3) & genset for power generation at University campus

|

||

Transfer of Technologies

AICRP on RES is working with the objective to develop and demonstrate renewable energy technologies suiting to rural sector for production agriculture, agro-processing and rural living. A number of useful solar and biomass based technologies have been developed under the project and demonstrated successfully at user’s sites in crop production and processing, animal raising, agro-industries and rural domestic applications.

|

|

|

||

| Training camp of modified solid-state biogas plant at Rawala, distt: Amravati for masons | Meeting with farmers at Ramanwadi, Tah: Radhanagari, Distt: Kolhapur (Mahrashtra) regarding propagation of modified solid-state biogas plant | Modified institutional solid-state Janta biogas plant of 10 m3 at Hare Krishna Gram village Aaravade, Tah- Tasgaon, Distt: Sangali (Maharashtra) |

Contact Information

Research Engineer

All India Co-ordinated Research Project on Renewable Sources of Energy for Agriculture Agro-based Industries

Dr. Panjabrao Deshmukh Krishi Vidyapeeth

Krishi Nagar, Akola – 444 104 (M.S.)

Phone & Fax No. (0724) 2259404